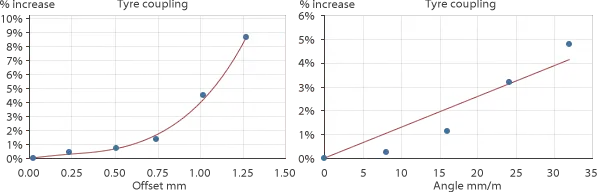

Figure 1 The effect on power consumption of misalignment

The graphs are reprinted from a report of the investigation into the effects of misalignment on power consumption that was carried out at the ICI Rocksavage Sire, Runcorn from 4th July - 16th August 1994.

The pump was installed to circulate water through a closed loop of piping with the motor running at 3000 rpm. The motor rating was 7.5 KW. Pure horizontal offsets and angular misalignment were introduced into the machine set, and the current drawn by the motor was recorded.

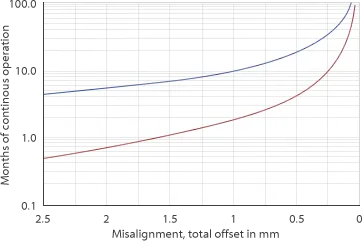

Figure 2 Mechanical seal time to failure due to shaft misalignment

In this graph, the lower threshold values are taken from the Durametallic Intec Training Handbook. Failure is defined when the seal starts to leak. In practise, the seals are not replaced immediately but continued to be used for some time. Based on data from AES Seals, the upper threshold values show seal life based on typical industry practice. For the purposes of this purchase justification, the more conservative upper curve is used.

Annual savings on plant when alignment is better than 0,05 compared to typical measured alignment of 9,00 mm.

| Saving on power costs | 4.210.005,85 € |

| Saving on replacement seals | 3.791,89 € |

| Saving on replacement bearings | 1.432,76 € |

| Saving on pump repairs | 10.427,69 € |

| Total additional cost over one year ** | 4.225.658,18 € |

| Total additional running cost of 5 year period ** | 21.128.290,92 € |

Total yearly cost of repair and power waste when aligned to +/- 0.05 MM OFFSET: 5.650,98 €